Connections are the weak point of all electrical circuits and especially earthing circuits subjected to aging and corrosion. The capacity of an earthing circuit to protect the safety of personnel depends on the quality of the connections made.

BS 6651 (1992) STATES

"Any joint other than welded represents a discontinuity in the current conducting system and is susceptible to variation and failure."

THE CADWELD PROCESS

makes it possible to produce copper/copper, copper/aluminum, copper/steel and aluminum/aluminum electrical molecular bonds with no external energy or heat source.

The principle consists of bringing together a welding filler material and ignition agent in a suitable graphite mould. The weld metal composition depends upon the metals to be welded (copper oxide and aluminum for a copper/copper weld). The reduction of copper oxide by aluminum produces molten copper and aluminium oxide slag at extremely high temperatures. The shape of the mold, its dimensions, and the size of the weldmetal, are all dependent on the items to be welded and their size.

THE BASIC PRINCIPLE

The welding material and starting powder are poured into the mold crucible. They are contained during the reaction, by means of a metal disc seat.

When the reaction is complete, the molten metal is released and flows down the tap hole onto the items to be welded in the weld cavity.

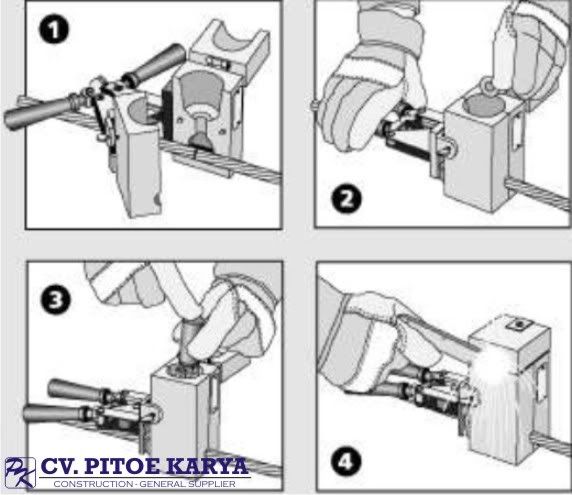

FOUR SIMPLE STEPS

STEP 1. Prepare conductor ends with a wire brush for welding. Place cable ends into open mold.

STEP 2. Close handles to lock mold halves together. Drop metal disk into crucible ensuring it is correctly seated, covering tap hole.

STEP 3. Deposit weld metal into crucible. Tap bottom of container to release starting material. Spread a little starting material on top of mold.

STEP 4. Close the cover and ignite with flint gun. Open the mould after 10 seconds, when metal has solidified.

For further information, kindly contact us.